Title: 42 Nos of Hopper Design

Client: Randen Engineering

Software used: PV-Elite/ANSYS/Autocad

Duration: 3 Months

Keywords: Pressure Vessel, Silo, Hopper, Rectangular Vessel, ASME SEC VIII Div 1, Good engineering practice, Storage tank, Storage Vessel, Agitator mounted Vessel

Scope:

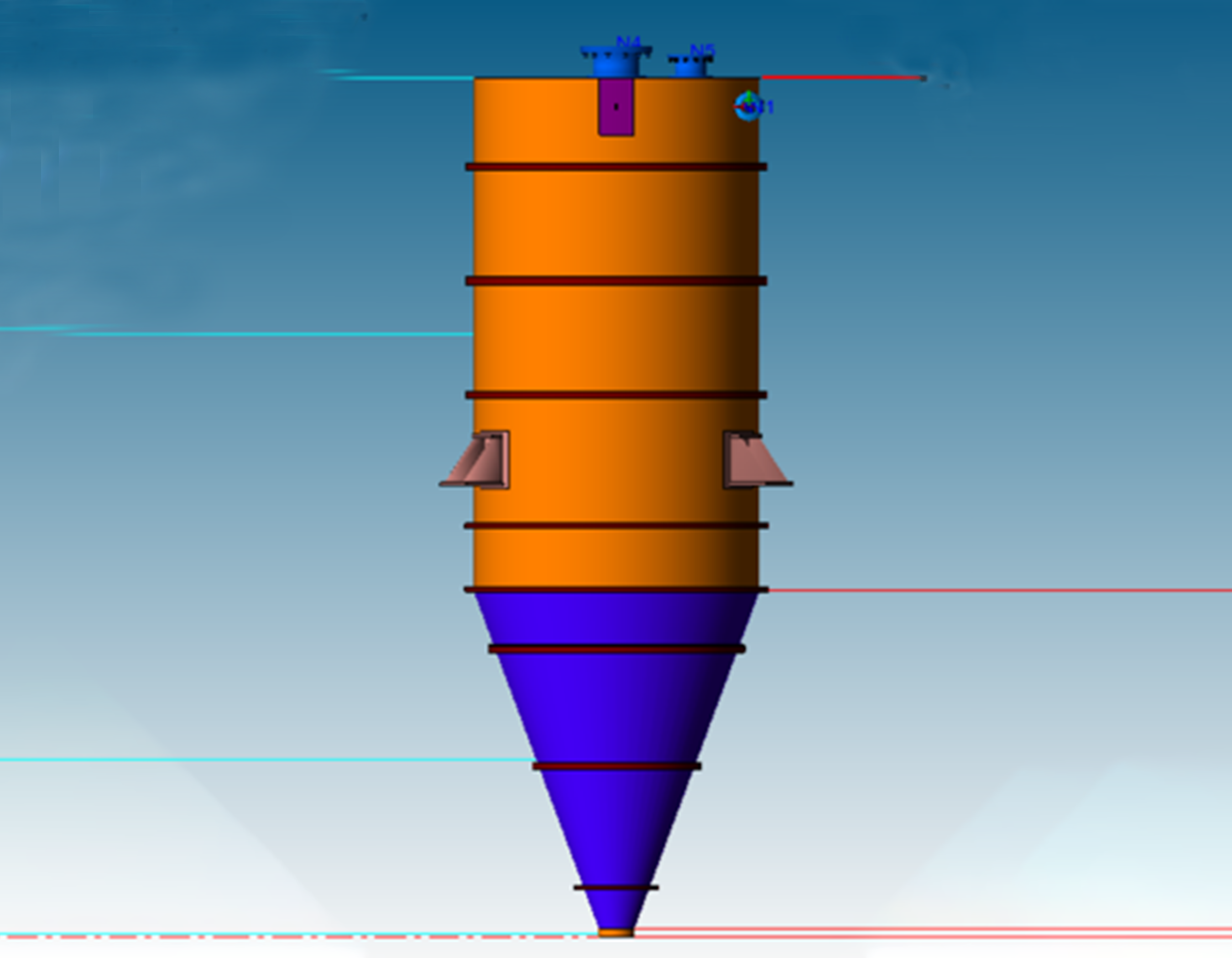

Design and Detail fabrication drawing preparation for 42 nos Circular and Rectangular hoppers as per ASME SEC VIII Div 1 and Good engineering practice.

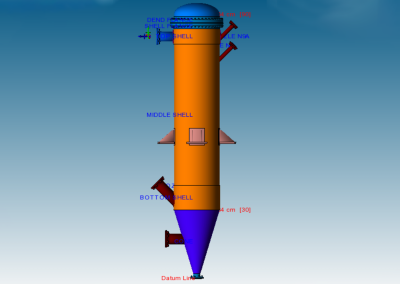

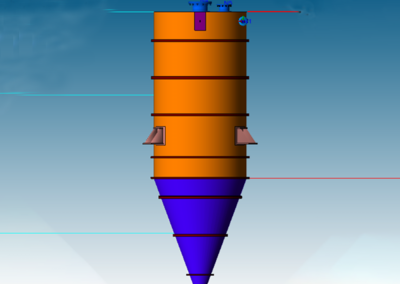

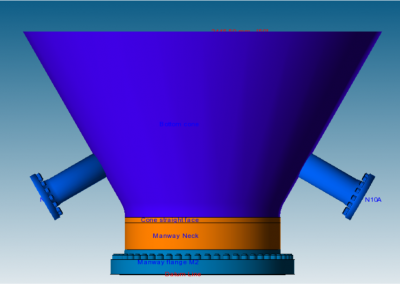

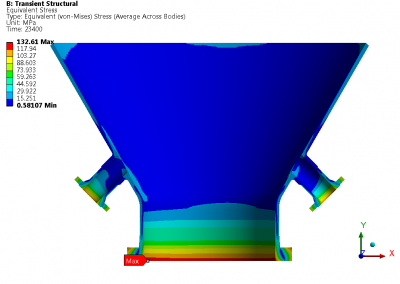

1) Design of 28 circular hoppers as per ASME SEC VIII Div 1 and Good engineering practice.

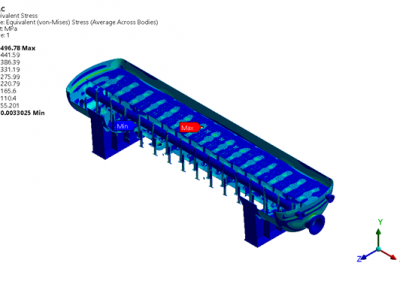

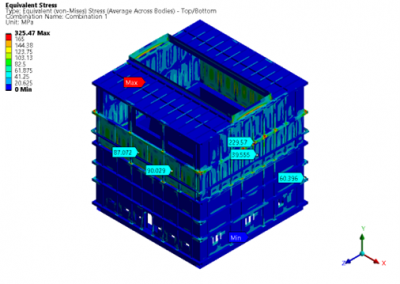

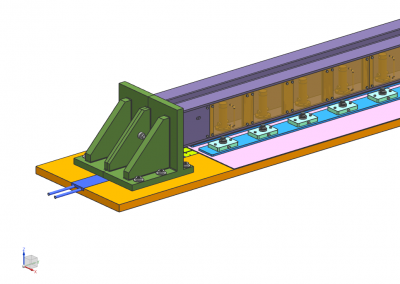

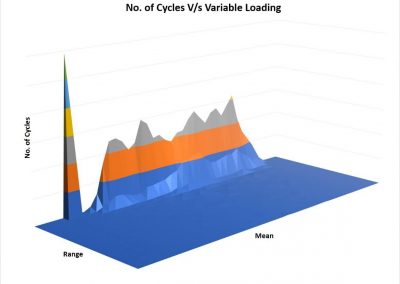

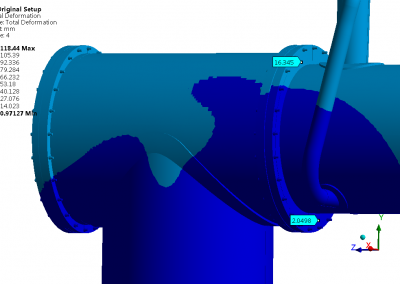

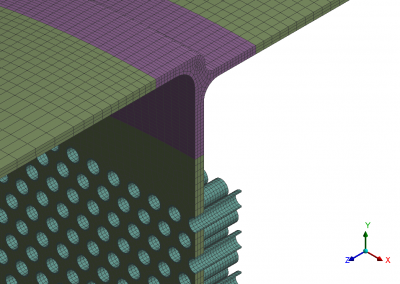

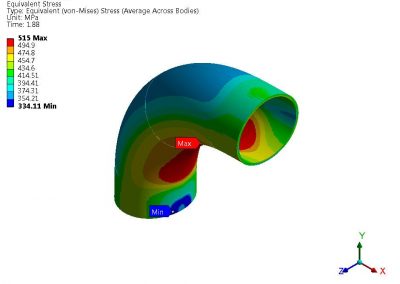

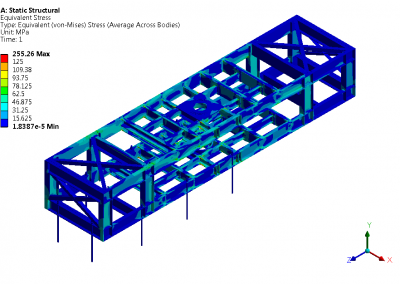

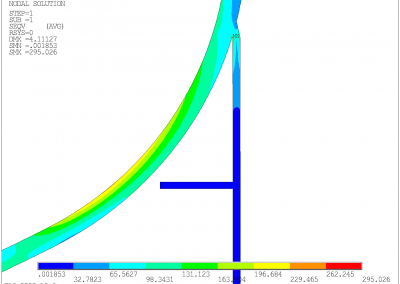

2) Design of 14 rectangular hoppers as per Good engineering practice and FEA for few parts.

3) Detail Fabrication drawing preparation.

4) Critical Requirement Sheet for procurement.

The end client for this project was from the FMCG industry, so deliverables were required at an incredible pace. Design for circular hoppers was performed using PV-Elite software; for non-circular hoppers in-house developed excel sheet was used. GA drawing was prepared based on design output and submitted for approval within one month for all the hoppers. Critical Requirement Sheet preparation for procurement was started after design submission and floated for inquiry. After design approval the sheet was corrected for small changes requested from the client. Detail fabrication drawing preparation was started based on the priority given by the client and completed in 35 days for all hoppers.

Benchmark: The project was faced paced to require a systematic approach and integration in design and drafting teams. The project was completed with great satisfaction to the client. The client was amazed at our support till the completion of the project.

Recent Projects